The Brewtools Brewing System

Brewtools B40pro,B80pro and B150 pro are designed for maximum flexibility. There are many ways of using the system based on personal prefrence, what kind of accessories you have and your your brewing area is set up. Below, we will explain the principles of the system and the possibilites it gives you.

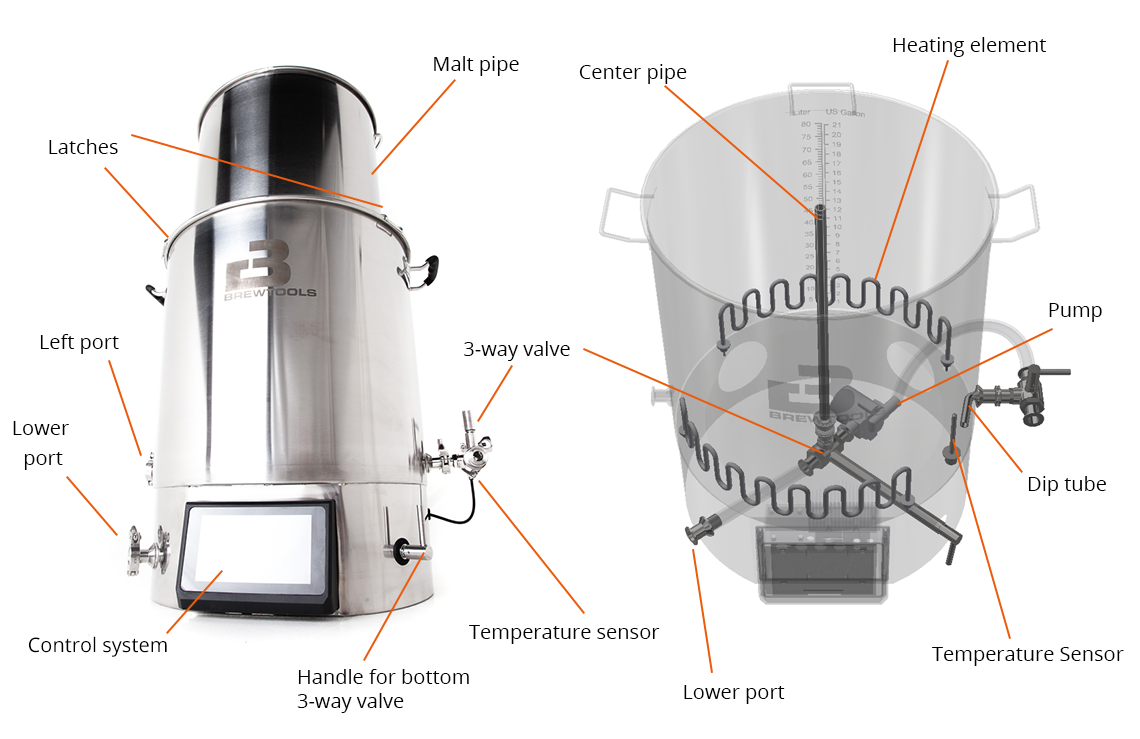

The tank and malt pipe is built from SS304 stainless steel with a thickness of 1.0.mm All outlets and ports on the tanks and valves are 34mm Tri-Clamp for maximum flexibility. The flanges and steel parts are cast in SS304 stainless steel, and CNC machined. The pump features a 24V brushless motor, it’s quiet and powerful and the speed is controlled from the touch-screen. All tubes are 16x25mm food grade high quality silicone, with high transparency. The entires system is designed and built to withstand rough use and many parts are manufactured by hand.

The basic principle in the system is a tank with a conical bottom with heating elements, a temperature sensor, a center pipe that’s easily removable, an outlet port on each side and a 3-way valve in the bottom which makes it possible to circulate both over the grains and through the lower outlet and counterflow cooler or tube at the same time with full flow control. This makes it easy to keep the maintain accurate temperature outside the malt pipe as you circulate the wort around and the malt pipe and up over the grains. The dip-tubes has two o-rings that makes them easy to adjust to the desired angle. If you brew with a lot of hops, you can adjust the dip-tube accordingly to prevent too much hops in the circulation and into the fermenter.

The right 3-way valve is used to choose the input for the pump. You can pump from the inlet dip-tube or from a second tank, usually for sparge water. In the standard setup without extra 3-way valves, this valve is also used to drain the wort to the fermenter.

The Control System

The Pro Series Control system is developed in-house at Brewtools and is the heart of the Pro brewing systems. The software is constantly being improved and new features added. You can download the latest version here. The system features a 7-inch touch display and a custom developed PCB with a powerful microcontroller (STM32F4 180mhz). It also has a communications module with WiFi and Bluetooth 4.2. The heating elements are controlled by two solid-state relays. The power supply (24V, 65W) power the pump and all the electronics. The system is identical for both the B40pro and the B80pro, but when installed in the B40pro it only utilises one of the two relays.

The Software

The software in the Pro Series control system, is continously being developed and we are bringing new features and improvements to the system. They are also working on developing a cloud service to set up your recipes. It will be also integrated with Brewfather. In this guide, you will find information on how the system works with all functions explained. The guide will be updated with new software releases.

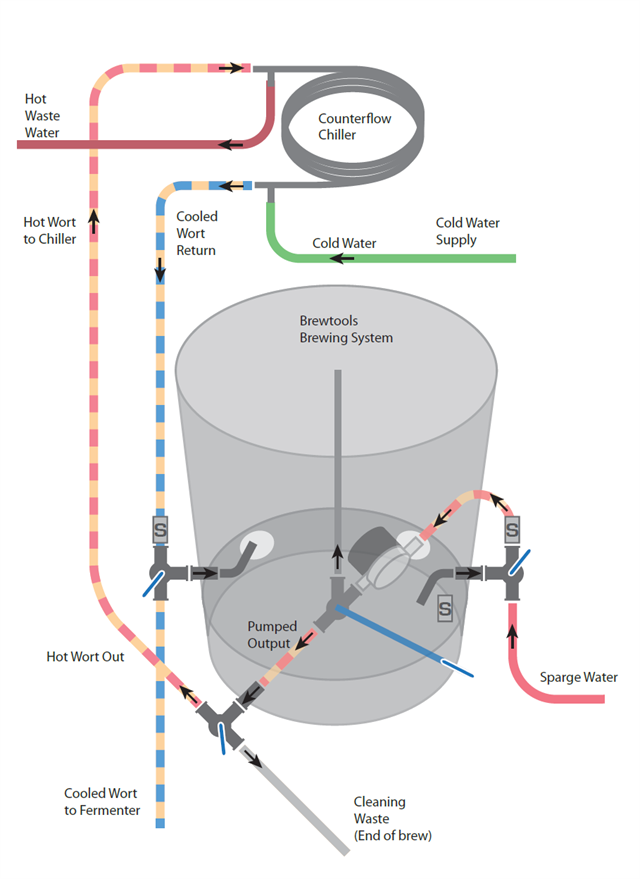

Standard setup

Out of the box, the B40pro and B80pro comes with one 3-way valve. This is a good start, and you can try the system and get to know if before you expand. You can circulate the wort over the grain, and it’s also possible to use a tube to circulate from the lower outlet to the left outlet and create a whirlpool (needs an extra dip tube) during mashing and also if you use an immersion cooler. You can also use our counterflow cooler for efficient cooling, without an extra 3-way valve on the left outlet. Using the system this way, you need to cool all of the wort down to pitching temperature before you drain to the fermenter. If you sparge using other methods, you can move the single valve to the left side, and combine it with a counterflow cooler. You connect the sensor holder directly to the right output port.

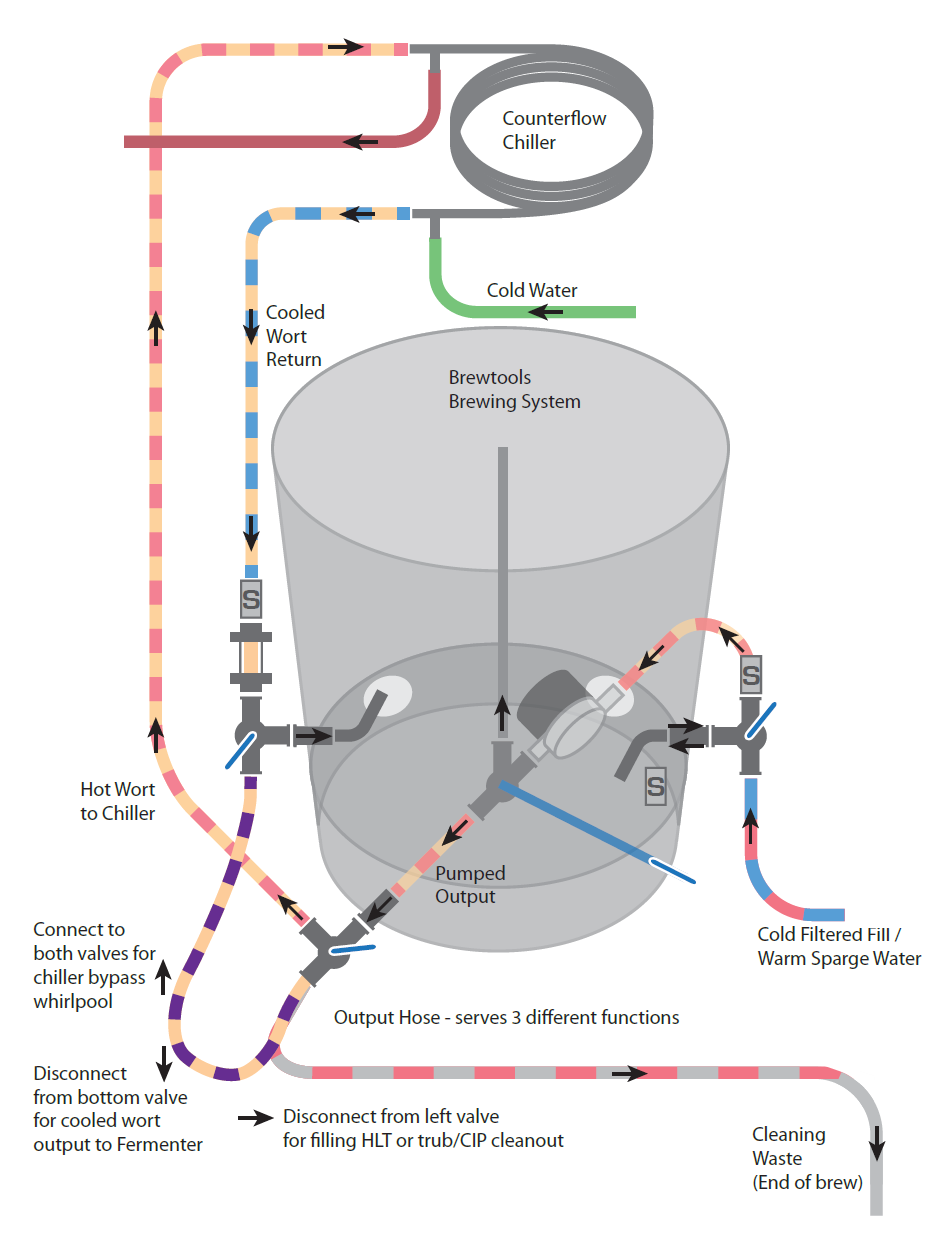

Three-valve setup

To avoid making a mess when disconnecting the cooler for cleaning and draining, many users want to have a third 3-way valve on the lower outlet. The brewing can be done without disconnecting tubes and it’s all very nice and tidy.