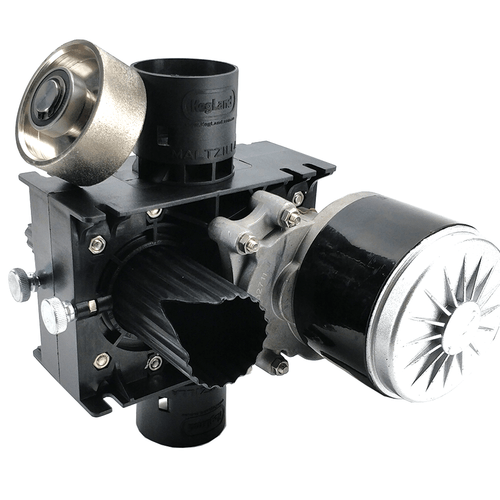

MaltZilla with Integrated 24v Motor - The Diamond Grain Mill - Premium Diamond Rollers

The long awaited MaltZilla is finally here. A large amount of research and development has gone into designing, manufacturing and testing the MaltZilla Diamond Mill.

It has an integrated high torque motor powerful enough to chew through popping corn kernels with ease. All you will need is to choose your choice of power supply (above), whether it be the simple Alligator Clips to attach to a battery. Or go for one of the preferred 24v slimline power supply options.

Historically other mill manufacturers have made grain mills from steel. In some other good quality mills they use harden the steel so that the knurling stays sharp for longer and continues to draw grain. With that said the knurling even on hardened steel will soon go blunt and this reduces the mills ability to draw grain well. Some other manufacturers attempt to solve this problem by using geared rollers so the rollers grab the grain slightly better or using 3 rollers whereby the first two rollers with a larger gap force the grain into the third roller. These options in our opinion do not solve the real issue which is that all of these steel rollers go blunt especially if hard grains are used like wheat or corn.

In a commercial setting it’s not uncommon to send the rollers off to a metalworking factory to re-sharpen and re-knurl however this is often uneconomical and a hassle to do. For smaller homebrew customers they might just end up throwing the mill away and purchasing a new one.

The MaltZilla Diamond Mill is quite a different mill design and it’s the first in the world to use diamonds impregnated into the surface of the roller. These diamonds even after many tons of grain are processed through the mill will stay just as sharp as they were on day one.

The sharpness of the diamonds really draws grain exceptionally well and even when hard products are used such as corn the diamond rollers simply smash it to pieces.

Grain Hopper

This unit does not come with a grain hopper as standard. Your choices are the Aluminium Hopper or a simple cost-effective alternative is using the 12L Aqua Bottle.

Large 70mm Diameter

The MaltZilla has 70mm large diameter rollers are double the diameter of many other mills. The large diameter significantly improve the crush and assist in drawing the grain in better.

Shear, Not Chop

Most mills require aggressive knurling to push into the grain and “chop” the grain as it passes through a tight gap. This often means your grains are chopped in half. The MaltZilla works on a different principle and gap setting is not as critical. The MaltZilla uses impregnated diamonds to grip the surface of the kernel and the friction of pulling the grain through the gap causes a sheering action. When set up correctly this can leave the entire husk intact reducing the chance of stuck sparge, improving efficiency while still opening the husk efficiently enough that the entire contents of the kernel is available to the mashing process.

Integrated Motor

You generally would not purchase a car without an engine or a blender without a motor. So why would you purchase a grain mill without one. Milling grain has an optimum RPM. Too slow and it will take you a long time and too fast and you will end up with excessive powder. The hand crank is really a pain in the backside and using a drill simply doesn’t give you the speed control that you require and often results in burning out your drill. The MaltZilla has an integrated motor. The motor has a very constant RPM putting out optimum RPM with an integrated gearbox. The high torque and sealed construction make it ideal for a brewing environment. The motor is well sealed from moisture and grain dust.

The motor is seamlessly integrated into the side body of the mill.

Being DC the motor is safer than higher voltage AC especially in an environment where washing down the area with a hose is likely to happen.

The DC motor is also reversible so the direction of spin can be changed based on the polarity. This is particularly useful for over-mount and under-mount installation.

Over-Mount and Under-Mount Installation

Traditionally most other mills just sit on a board where they are moved from one bucket to another. The Maltzilla has multiple different mounting configurations. It can be over-mounted to a board like most mills are however if you want a seamless finish to your garage/brewing area you can mount the mill under your counter where it’s concealed and out of the way. Simply lift up a small opening in the top of your benchtop, drop in the hopper and then pour the grain into the hopper. When you are done remove the hopper and replace the lid.

From: Kegland